Innovations in Gender Sorting: Behind the Scenes with Genesys

In the fast-evolving world of business technology, the role of gender sorting in poultry production has reached new heights. As the industry adapts to changing market demands and the need for efficient communications, understanding the underlying processes and innovations becomes increasingly crucial.

This article delves into the transformative practices in gender sorting, shedding light on how a system like Genesys is redefining standards in the global poultry sector. With a focus on accuracy, workforce challenges, and the rise of technology, we aim to provide a comprehensive overview of how these advancements are shaping the future of poultry farming.

Key Takeaways:

- Gender sorting ensures product uniformity and meets retailer expectations.

- Manual sorting is slow, labor-intensive, and prone to human error.

- Genesys automates sorting with over 97% accuracy, improving speed and reliability.

- Modular, compact design allows seamless integration into existing hatcheries.

- Real-time monitoring and data insights support smarter decisions and higher efficiency.

- Automation is key to meeting future challenges in poultry production sustainably.

Understanding Gender Sorting in Poultry Production

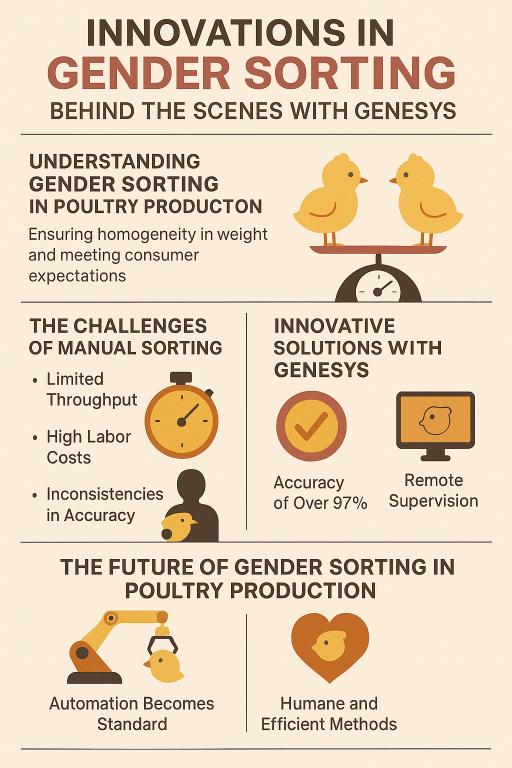

Gender sorting in poultry production is not just about separating male and female chicks; it’s about ensuring homogeneity in weight and meeting consumer expectations. In today’s market, retailers demand precision in weight for poultry products, making gender sorting an integral part of the production process. The use of data-driven methodologies has revolutionized how producers approach this task. By leveraging modern technology, producers can ensure that their outputs align with market specifications.

The traditional method of gender sorting relies heavily on manual labor, where operators assess physical traits of chicks at the time of hatching. This practice, while effective, poses significant challenges, including variability in accuracy due to human error. As a result, the poultry industry faces increasing pressure to adopt more reliable techniques.

Incorporating technology not only enhances precision but also addresses the pressing issue of labor shortages. As fewer workers are available for manual sorting, automating the process becomes essential for maintaining productivity and quality. This shift leads to significant changes in how producers operate, ultimately benefiting both the business and consumer experience.

The Challenges of Manual Sorting

Despite the importance of gender sorting, the manual method presents numerous challenges that can hinder production efficiency. As companies strive to maintain a competitive edge, understanding these challenges is vital. One critical issue is the limited throughput of manual gender sorting. Operators can typically sort no more than 2,500 chicks per hour, which becomes a bottleneck for larger operations.

For example, a hatchery with a capacity of 1.2 million chicks per week may require up to 20 operators engaged in sorting activities at all times. This requirement intensifies the strain on resources, especially given the current trend of workforce shortages across various industries. The reliance on manual processes not only raises costs due to labor expenses but also increases the risk of errors in gender identification, which can lead to operational inefficiencies.

Furthermore, variations in operator skill and experience can lead to inconsistencies in sorting accuracy. Ultimately, these factors can affect meat quality and consumer satisfaction, emphasizing the need for innovative solutions that can streamline these processes with greater reliability.

Innovative Solutions with Genesys

Genesys system has emerged as a leader in providing innovative solutions that address the challenges faced in gender sorting. By integrating advanced algorithms and automation, Ceva Genesys has developed a system that significantly enhances the accuracy of gender sorting. This system boasts a remarkable precision rate of over 97%, ensuring that producers can meet the high standards expected by consumers and retailers alike.

One of the key features of the Genesys technology is its modular design, which allows for easy integration into existing hatchery setups. The compact nature of the equipment means it can fit into various configurations, optimizing the flow of chicks and minimizing disruption during sorting. This streamlined approach not only improves accuracy but also enhances overall operational efficiency.

Additionally, the Genesys system includes remote supervision capabilities, enabling hatchery managers to monitor performance in real time. This feature allows for proactive identification of performance deviations and facilitates timely troubleshooting.

The continuous data recording of production outcomes and performance indicators provides valuable insights, empowering managers to make informed decisions that elevate their business’s success.

The Future of Gender Sorting in Poultry Production

As the poultry industry evolves, the importance of gender sorting will only increase. The integration of technology into this process will redefine how hatcheries operate, driving improved efficiencies and outcomes. With innovations like those introduced by Genesys, producers are better equipped to navigate the complexities of poultry farming in a highly competitive global market.

Looking ahead, we anticipate that automation will become the standard in gender sorting practices. This shift will not only address workforce challenges but also ensure that producers can consistently meet the demands of an ever-changing market. As more companies adopt these advanced technologies, we can expect to see significant improvements in productivity, product quality, and overall market competitiveness.

Moreover, as public awareness of animal welfare and sustainable farming practices grows, the pressure to adopt humane and efficient sorting methods will intensify. The solutions implemented today will serve as the foundation for a more sustainable and efficient poultry industry tomorrow.

The landscape of poultry production is undergoing a significant transformation driven by the need for efficiency, accuracy, and sustainability. Innovations in gender sorting, particularly through the work of systems like Genesys, are setting new standards that benefit producers and consumers alike. By embracing these advancements, the poultry industry can enhance its operational capabilities while addressing critical challenges such as labor shortages and market demands.

As we move forward, the integration of technology will be pivotal in shaping a more resilient and efficient industry. Understanding and adapting to these changes not only prepares businesses for the future but also fosters a more sustainable approach to poultry farming.

The commitment to continuous improvement and innovation will ultimately lead to a brighter future for the industry, ensuring that it can thrive in an increasingly competitive environment.

Post Comment