Industrial robotics: enhancing precision and productivity

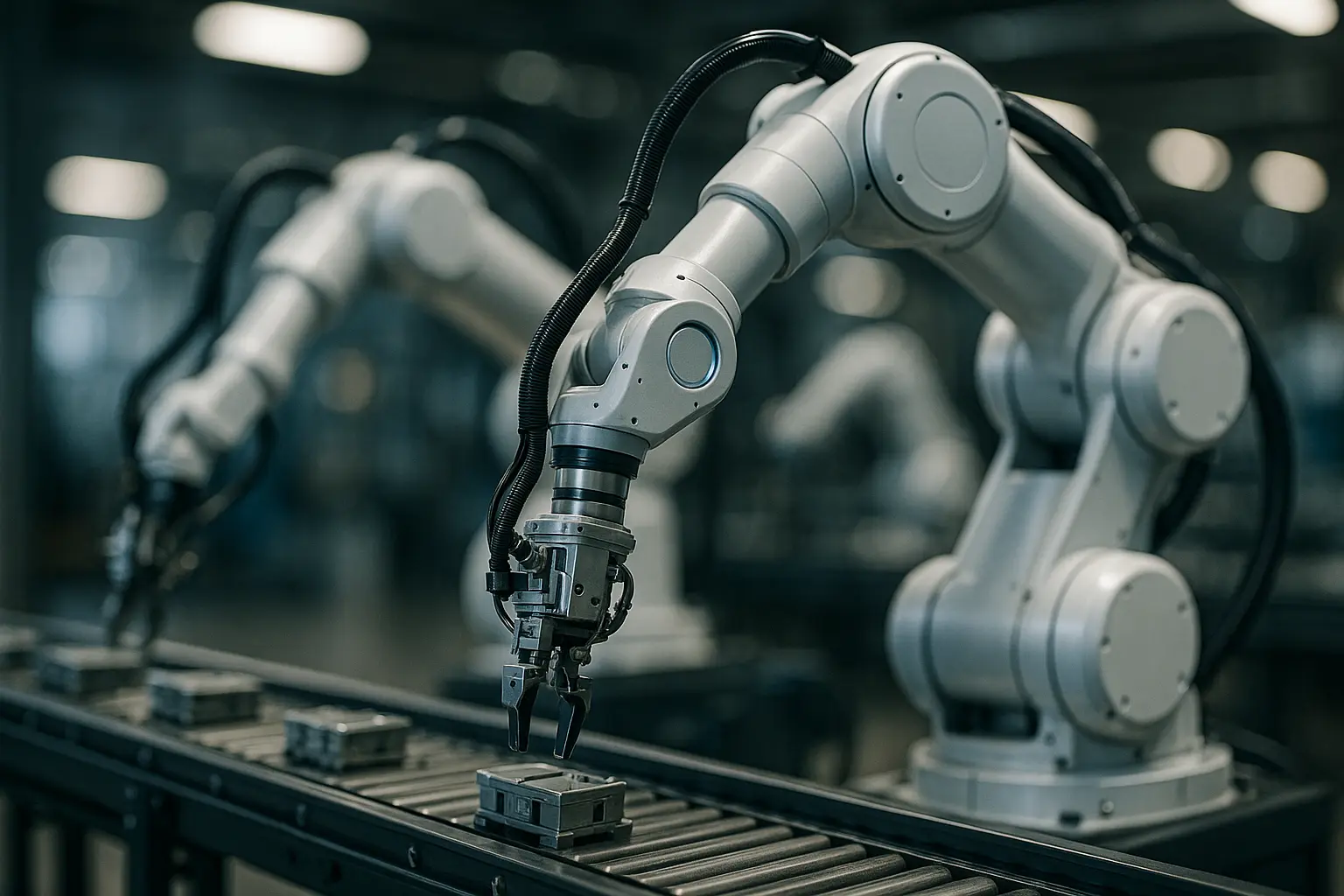

Welcome to the dawn of a new era in which robots and robotics aren’t just buzzwords; they’re active players reshaping the industrial landscape. As we stride confidently through this exciting time, we must understand how these mechanical marvels are not only changing how we manufacture but also enriching our everyday experiences.

Imagine a world where factories hum with the synchronized precision of a well-rehearsed orchestra, where automation and human ingenuity work hand in hand. This isn’t a distant dream—this is the reality of manufacturing today. Join us as we explore the fascinating world of industrial robotics, where the lines between man and machine blur, leading to unprecedented levels of productivity and efficiency.

The Rise of Robotics in Manufacturing Systems

Robots are swiftly moving from the realm of science fiction into the tangible world of industrial production. As the demand for increased efficiency and precision rises, the manufacturing world has turned its gaze towards robotics to meet these needs. These dynamic machines are not only revolutionizing the way we produce but are also enhancing the overall quality of the output.

Robotic systems are designed to tackle tasks that were once considered too dangerous or monotonous for humans. From assembling intricate electronics to welding automotive parts with pinpoint accuracy, robots are proving their worth repeatedly. They are ushering in a phase where human workers are relieved from repetitive tasks, allowing them to focus on more complex problem-solving roles.

Moreover, the incorporation of robots into manufacturing systems is fostering an environment where learning and adaptation are paramount. These systems are continually refining their processes, thanks to advancements in automation technology. As a result, we are witnessing a significant boost in productivity, with factories becoming ever more streamlined and efficient.

The future of industry lies in a symbiotic relationship between humans and machines. By leveraging robotics, we can ensure that our production systems are not only more productive but also safer, minimizing potential hazards that workers face daily.

Automation and Precision: The Hallmarks of Modern Robotics

In today’s fast-paced world, the need for precision in manufacturing is paramount. Robotics, with its unmatched capability for accuracy, stands at the forefront of this revolution. By automating critical tasks, we can ensure that every product crafted meets the stringent standards of modern-day quality control.

Automation allows for the consistent replication of tasks without the variability introduced by human fatigue or error. This consistency is vital in industries such as pharmaceuticals, where even the tiniest deviation can have monumental consequences. By entrusting these tasks to robots, manufacturers can ensure a level of quality that meets global standards without compromising on safety.

Furthermore, the integration of robotic systems into production lines reduces waste and optimizes resource usage. By ensuring each process is executed with the utmost precision, we can maximize material usage and minimize excess, leading to more sustainable practices. This efficient use of resources not only benefits the environment but also enhances the overall efficiency of manufacturing processes.

As we stand on the brink of a new industrial revolution, it’s evident that robots are more than mere instruments—they’re game-changers. By embracing the capabilities of robotics, we are paving the way for a future where quality and precision are the norms, not exceptions.

Balancing Human and Robotic Collaboration: Towards a Seamless Future

The narrative of industrial robotics isn’t solely about the rise of machines—it’s about creating a harmonious balance between human effort and robotic precision. While robots are exceptional at executing predefined tasks with precision, they thrive best under the guidance of human oversight, making the collaboration both powerful and essential.

Workers bring to the table their creativity, intuition, and empathy—qualities that robots can’t emulate. By harnessing these human attributes alongside robotic efficiency, we unlock new levels of productivity that neither could achieve alone. This shift in industry means redefining roles—workers are transitioning from traditional roles to that of operators, programmers, and supervisors.

This collaboration also underscores a vital point: the integration of robots aims not to replace but to augment human capabilities. By offloading repetitive and hazardous tasks, we allow workers to engage in more meaningful and creative pursuits. This not only enhances job satisfaction but also propels companies towards innovative solutions that drive competitive advantage.

In our pursuit of future-ready manufacturing systems, we must ensure that training and development keep pace with technological advancements. Equipping workers with the skills needed to operate and interface effectively with robots is crucial for fostering a collaborative and seamless future.

As we gaze toward the horizon, the road ahead is paved with potential and possibilities. Industrial robotics is more than just an evolution; it’s a revolution that promises to reshape the manufacturing landscape as we know it. With robots leading the charge, the future is bright with innovation, efficiency, and the promise of a more harmonious coexistence between man and machine.

In this unfolding narrative, we’re not merely observers but active participants in a world where automation enhances human productivity rather than stifles it. By embracing the strengths of both humans and robots, we can ensure that the industries of tomorrow are not just more efficient but also more humane.

As we continue this journey, let us remain committed to fostering environments that prioritize safety, quality, and continuous learning. By doing so, we will not only enhance our present but also secure a future where industrial robotics and human innovation go hand in hand. Together, we are poised to usher in an era of unprecedented precision and productivity.

FAQ

What are industrial robots, and how do they enhance manufacturing processes?

Industrial robots are programmable machines designed to perform tasks in manufacturing environments. They enhance processes by increasing precision, reducing human error, and improving production speed, leading to higher quality products and more efficient operations.

In what ways do industrial robots contribute to increased productivity?

Industrial robots contribute to productivity by automating repetitive tasks, operating around the clock without fatigue, and performing tasks faster than humans, thereby increasing output and efficiency in manufacturing settings.

How do industrial robots improve precision in manufacturing?

Industrial robots are equipped with advanced sensors and control systems that allow them to perform tasks with high accuracy and consistency. This precision reduces material waste and ensures uniformity in the production of goods.

What industries benefit most from the integration of industrial robotics?

Industries such as automotive, electronics, aerospace, and pharmaceuticals see significant benefits from industrial robotics due to their need for high precision, efficiency, and the ability to handle complex, repetitive tasks.

Are there any challenges associated with implementing industrial robots in manufacturing?

Yes, challenges include the high initial cost of investment, the need for skilled personnel to program and maintain robots, and the potential for disruption in the workforce. However, these can be mitigated with proper planning and training.

Post Comment