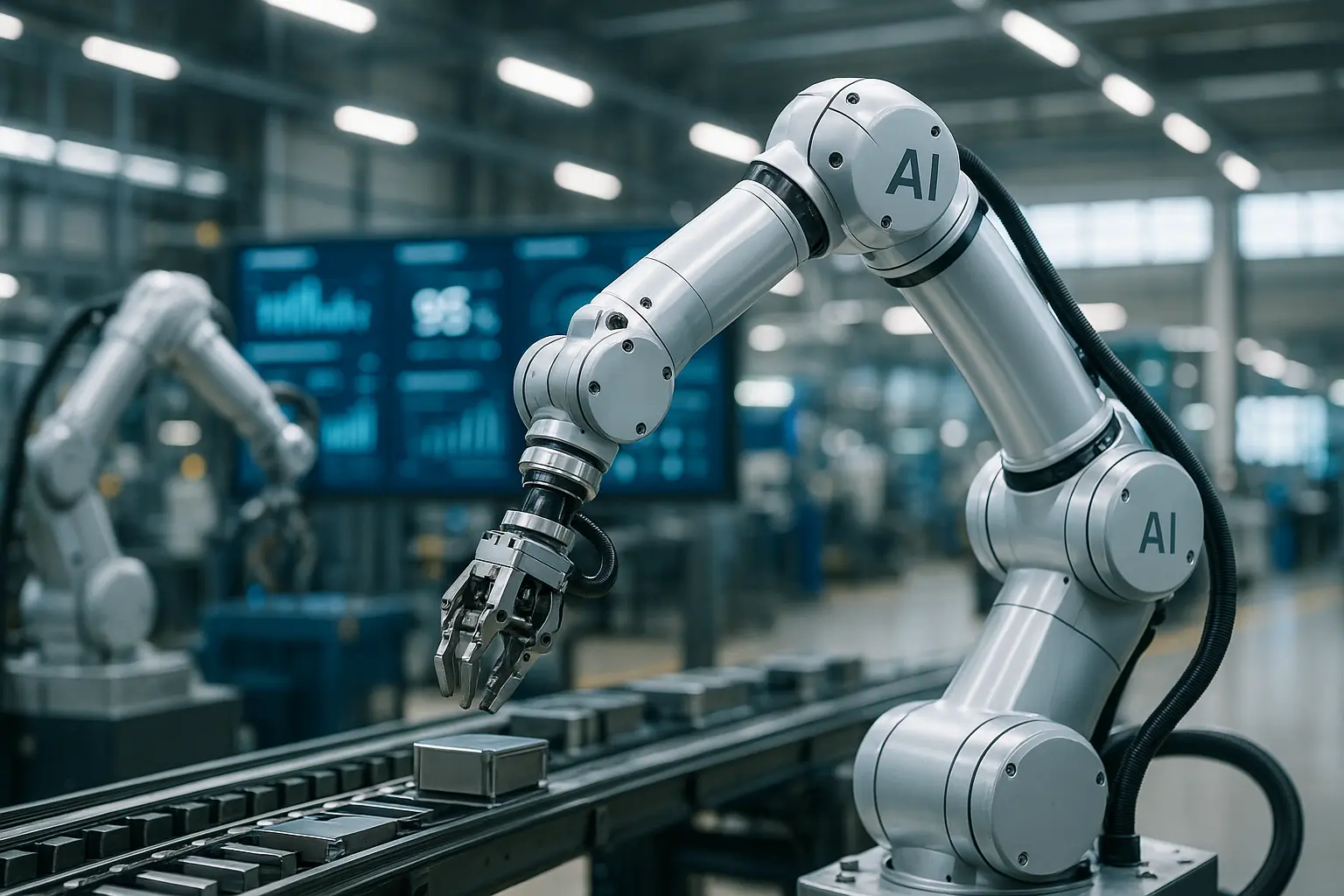

AI in industry: transforming operations and efficiency

The world of industry is evolving at breakneck speed, and artificial intelligence is at the very heart of this transformation. Today, AI is not a distant promise; it is the present reality that powers the engines of our businesses. With the dawn of smart manufacturing, we are witnessing a revolution in operations, where efficiency and precision are no longer aspirations but achievable outcomes. AI stands as a catalyst, breathing new life into operational systems and processes, enabling companies to stay ahead of the curve. This article will delve into the myriad ways AI is reshaping the business landscape, offering insights into how we can harness its potential to improve quality, enhance productivity, and ensure seamless customer experiences.

AI-Powered Systems: The Backbone of Modern Operations

While many of us might picture AI as a futuristic concept, its applications are increasingly critical in today’s manufacturing landscape. AI-powered systems are not just tools; they are partners in achieving operational excellence. By integrating AI into our processes, we can drive efficiency and refine tasks, reducing time and resources spent on mundane activities.

Imagine a world where predictive intelligence takes center stage. AI can sift through mountains of data to predict equipment malfunctions before they occur, allowing us to address potential issues without disrupting the supply chain. This predictive capability translates into fewer downtimes and improved productivity, as our systems can anticipate needs and adapt accordingly.

The power of AI extends beyond mere anticipation. Real-time data management enables us to make informed decisions swiftly, ensuring our businesses remain agile and responsive. With AI, we can optimize processes, streamline operations, and enhance overall quality. The integration of AI into our operations is not a mere adjustment; it’s a complete transformation, allowing us to achieve outcomes that once seemed unattainable.

Streamlining Business Processes with AI

Every forward-thinking organization recognizes the importance of streamlining processes to maintain a competitive edge. By adopting AI, we can transform traditional business models into dynamic, efficient ecosystems that respond to market demands with unprecedented speed and precision.

AI’s role in process automation enables us to handle repetitive and time-consuming tasks with ease. This automation not only frees up valuable time but also enhances productivity by allowing human intellect to focus on strategic initiatives. This delicate balance between machine efficiency and human ingenuity is what sets modern businesses apart.

AI also aids in data-driven decision-making, giving us the ability to analyze operational patterns and derive actionable insights. With AI, we can optimize resource allocation, minimize waste, and ensure our processes align with quality standards. This synergy between technology and human expertise creates an environment where businesses can flourish, driven by a culture of continuous improvement.

Moreover, with AI, we can tailor our customer experiences to meet individual preferences, enhancing satisfaction and fostering loyalty. In a world where customer expectations are ever-growing, AI’s ability to predict and adapt is invaluable.

AI: Redefining Quality and Productivity

In today’s competitive landscape, the concepts of quality and productivity are more intertwined than ever. AI serves as a bridge between these two pillars, enabling us to deliver high-quality products while maximizing efficiency and reducing costs.

With AI, we can monitor production lines in real-time, identifying potential quality issues before they escalate. This proactive approach ensures that our businesses maintain their reputation for excellence, delivering products that meet and exceed customer expectations.

The incorporation of AI into our manufacturing processes also enhances productivity by optimizing the use of resources. By utilizing AI-driven analytics, we can identify bottlenecks and implement solutions that streamline operations, reduce waste, and sustain momentum.

Furthermore, AI empowers us to take a holistic view of our supply chains, ensuring that every link operates harmoniously. This interconnectedness enables us to adapt to changes swiftly and maintain a steady flow of materials, ultimately enhancing our operational efficiency.

In essence, AI enables us to operate with an unparalleled level of precision, ensuring that we deliver quality without compromising on productivity. This balance is critical as we navigate the modern business terrain.

In the ever-evolving landscape of industry, embracing AI is not merely an option; it’s a necessity. As we strive to transform our operations, we must recognize the transformative potential of AI-powered systems. The fusion of intelligence, data, and human ingenuity can propel our businesses to new heights.

By integrating AI into our processes, we can achieve unprecedented levels of efficiency, redefining what it means to be productive and innovative. The journey towards operational excellence demands that we harness the full breadth of AI’s capabilities, ensuring that our businesses remain resilient and adaptive in a world of constant change.

As we look to the future, let us embrace this transformation with open arms, trusting in the power of AI to guide us toward a future where quality and productivity are not just objectives but enduring realities. Together, we stand at the precipice of a new era, ready to redefine our businesses and the industries we serve.

FAQ

How is AI transforming industry operations?

AI revolutionizes industry operations by automating routine tasks, optimizing supply chain management, and enhancing decision-making processes through predictive analytics.

What industries benefit most from AI integration?

Industries such as manufacturing, healthcare, finance, and logistics are experiencing significant benefits from AI integration, as it streamlines processes and boosts productivity.

How does AI improve efficiency in manufacturing?

AI enhances manufacturing efficiency by predicting equipment failures, optimizing resource allocation, and automating quality control, thus reducing downtime and waste.

Can AI help in reducing operational costs?

Yes, AI can significantly reduce operational costs by optimizing resource usage, minimizing errors, and enabling more efficient production schedules, resulting in cost savings.

What challenges do industries face when implementing AI?

Industries often face challenges like data privacy concerns, the need for substantial initial investment, and the requirement for skilled personnel to manage AI systems.

Post Comment