How Are Robots Changing Modern Manufacturing?

In the bustling world of modern manufacturing, robots are not just a luxury anymore; they’re a necessity. Imagine a world where efficiency and precision coexist seamlessly, where monotonous tasks are a thing of the past, and where production floors hum with the rhythm of robotic choreography. We are living on the cusp of such an era. Robotics has revolutionized the industry, offering a fresh narrative where human ingenuity and robotic prowess collaborate to redefine the boundaries of what’s possible. Welcome to a world where automation is no longer about replacing us but empowering us.

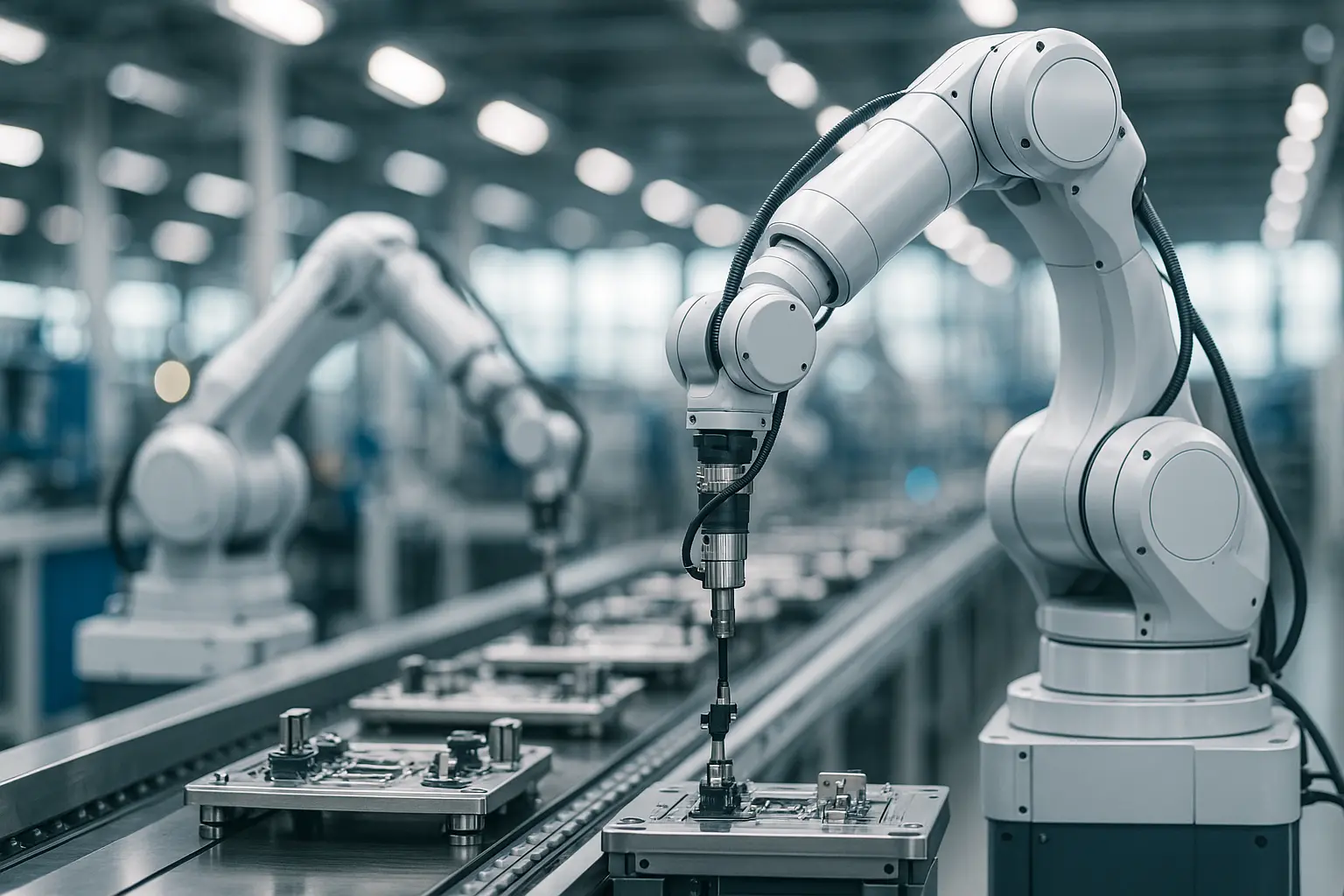

The Rise of Robotics in the Manufacturing World

Manufacturing has always strived for efficiency, from the days of the first Industrial Revolution to today’s digital age. The introduction of robots into our industrial processes has marked a pivotal shift, not just in how we approach production, but in how we perceive it.

The Evolution of Robotics

Back in the early days, when robots first entered the factory floors, they were bulky, one-dimensional, and often intimidating. But as technology advanced, these mechanical titans began to evolve. Today’s robotic systems are agile, intelligent, and versatile, designed to work alongside workers rather than replacing them.

Redefining Tasks and Roles

With robots taking over repetitive and hazardous tasks, human workers have found themselves in roles that prioritize oversight, creativity, and problem-solving. We are no longer confined to the drudgery of production lines; instead, we are free to innovate, oversee, and enhance processes with our unique human touch.

A Synergy of Human and Machine

This isn’t a world where humans are replaced, but rather one where we work hand in hand with advanced robotic systems. We design, program, and monitor these machines, ensuring they operate at optimal levels, while they take on tasks that were once deemed too tedious or dangerous for us.

The Future Outlook

As we look to the future, the integration of robots in manufacturing will only become more profound. The ongoing development of advanced technologies promises even greater collaboration, with robots adapting to human needs, learning from their environment, and continually pushing the boundaries of efficiency and innovation.

The Impact on Production Efficiency

Production efficiency is the heartbeat of any manufacturing environment. In today’s competitive landscape, it’s not just about producing more; it’s about producing better. Robots have become the champions of this cause, driving efficiency to new heights.

Precision and Consistency

One area where robots excel is in precision. The margin for error is drastically reduced when tasks are automated, leading to consistent, high-quality outputs. This is particularly vital in industries where accuracy is non-negotiable, such as pharmaceuticals or electronics.

Speeding Up Production

Time is of the essence in manufacturing. Robots work tirelessly around the clock, unaffected by fatigue or distraction, ensuring that production schedules are met with remarkable speed. This 24/7 capability significantly surpasses human limitations, allowing us to meet rising demands and tight deadlines with ease.

Cost-Effectiveness

While the initial investment in robotic technology can be hefty, the long-term savings are undeniable. By minimizing waste, reducing downtime, and maximizing efficiency, robots help companies save on labor costs, resource allocation, and operational expenses.

Enhancing Human Roles

As robots take on the labor-intensive tasks, human workers are free to engage in more strategic duties. This transition is not simply about shifting responsibilities but about elevating our roles to focus on innovation, strategy, and growth.

The Role of Advanced Systems

Modern robotic systems are equipped with sensors, AI, and machine learning capabilities, allowing them to adapt to changing environments. This adaptability ensures that production remains agile, responsive, and efficient, even as market demands evolve.

Challenges of Integrating Robots in Industry

Despite the many benefits, the integration of robots into the manufacturing world does not come without its challenges. Understanding these hurdles is crucial for successfully navigating this new era of automation.

The Cost Conundrum

While the long-term benefits are evident, the upfront costs of robotic systems can be prohibitive for smaller enterprises. We must carefully evaluate our return on investment and seek innovative financing solutions to make this technology accessible to all.

Training and Skill Development

As automation becomes more prevalent, the skill sets required for human workers evolve. Workers need to be trained not only to operate these machines but to collaborate with them. This calls for a paradigm shift in education and mentorship programs, emphasizing technology literacy and digital skills.

Job Security Concerns

One of the most significant concerns surrounding robotics in manufacturing is the fear of job displacement. It’s essential to communicate that these changes are not about lessening our value but enhancing it. Robots take on the monotonous tasks, allowing us more time for creative, strategic, and human-centric work.

Maintaining Safety Standards

Integrating robots into the workplace must be done with a steadfast commitment to safety. Ensuring that human and machine interactions are seamless and safe is paramount. Establishing robust safety protocols and regular system checks is crucial to maintaining a harmonious work environment.

Keeping Pace with Technological Advancements

The pace of technological advancement is relentless, and staying ahead can be challenging. To maximize the potential of robotic systems, we must remain vigilant, adaptable, and always eager to learn and innovate.

The Future of Robotics in Manufacturing

As we gaze into the future, the world of manufacturing is poised for even more exciting transformations. With robots at the helm, our industry stands on the brink of a new dawn, one that promises innovation, growth, and unprecedented possibilities.

Emerging Technologies

The robotic landscape is continuously evolving, with advancements in AI, machine learning, and IoT leading the charge. These technologies promise to usher in a new era of automation, where systems can learn, adapt, and even predict future needs, offering us unparalleled efficiency.

Human-Centric Focus

Despite the rising prominence of robots, the future of manufacturing will continue to be human-centric. The relationship between human and machine will evolve into a seamless partnership, where our unique intuitive thinking complements the machine’s precision and endurance.

Sustainable Manufacturing

Robots play a crucial role in pushing the envelope for sustainable production. From reducing waste to optimizing resource use, they enable us to adopt greener practices, helping industries minimize their carbon footprint and foster a more sustainable future.

Workforce Evolution

The role of workers in the industry will undergo significant changes. As we embrace technology, we must also invest in reskilling programs, ensuring our workforce is prepared to navigate the challenges and opportunities of a robotic future.

Embracing a New Era

In conclusion, the future of manufacturing is not just about the technology we adopt but how we integrate it into our lives. As we embrace this new era, we find ourselves not at the mercy of machines, but as orchestrators of a harmonious symphony, where human creativity and robotic efficiency create a melody of progress and prosperity.

The integration of robots into the manufacturing landscape has undeniably transformed our industry. While the journey is fraught with challenges, the possibilities are boundless. As we move forward, it’s not merely about adapting to technology but about harmonizing with it.

In this evolving dance between human and machine, we find new ways to amplify our capabilities, ensuring that the future of manufacturing is not just bright, but radiant. Together, with robots as our allies, we can forge a world where innovation knows no bounds, and where the echoes of progress resonate far beyond the factory walls.

FAQ

How are robots enhancing efficiency in manufacturing?

Robots are significantly boosting manufacturing efficiency by automating repetitive tasks, ensuring consistent output, and minimizing human error. This leads to faster production rates and reduced downtime, improving overall productivity.

What role do robots play in quality control within factories?

In quality control, robots utilize advanced sensors and cameras to perform meticulous inspections. They detect defects with high precision, ensuring that only products meeting the required standards proceed down the production line, thus maintaining high quality.

How do robots contribute to workplace safety in manufacturing?

Robots handle hazardous tasks, reducing the risk of injuries for human workers. By taking on roles that involve heavy lifting, exposure to harmful substances, or operating in dangerous environments, robots help create a safer work atmosphere for employees.

Can robots adapt to changes in production processes?

Yes, modern robots are designed to be highly adaptable. With advancements in machine learning and AI, they can be reprogrammed or retrained to accommodate new tasks, materials, or production methods, making them versatile assets in dynamic manufacturing environments.

How are robots influencing labor dynamics in the manufacturing industry?

While robots replace some manual tasks, they also create new opportunities for specialized roles in robotics maintenance and programming. The shift encourages workforce upskilling, leading to more technical and supervisory positions within the industry.