Scaling Up for High-Volume Sorting: How Genesys Meets Industry Demands ?

In today’s fast-paced environment, industries are consistently challenged to meet growing demands. In the poultry sector, where high volume sorting is crucial, efficient systems must be deployed to address issues such as labor shortages and precision requirements. The Genesys system stands out as an innovative solution that revolutionizes the sorting process for poultry hatcheries, enhancing both productivity and accuracy.

This article explores how the Genesys technology meets these industry demands, enabling support teams and agents to provide exceptional service, streamline operations, and ultimately improve customer experience.

Key Takeaways:

- Manual sorting is slow, imprecise, and labor-intensive.

- Genesys automates sorting with 97%+ accuracy and high speed.

- Compact design fits easily into existing hatcheries.

- Real-time data improves operations and product consistency.

- Enhances customer satisfaction and supports sustainable growth.

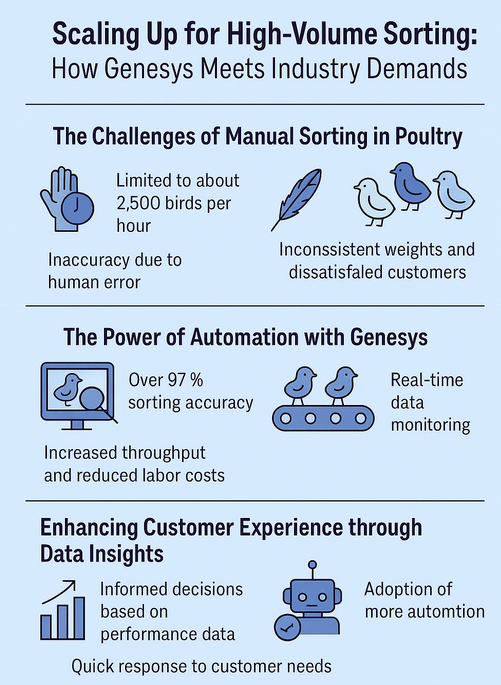

The Challenges of Manual Sorting in Poultry

Sorting poultry by gender has traditionally been a manual process, fraught with several challenges. One of the primary concerns is the time it takes to accurately identify male and female chicks. Manual sorting can limit output to approximately 2,500 birds per hour, which is insufficient for large hatcheries producing over a million chicks weekly. This bottleneck forces reliance on numerous operators, often leading to labor shortages and increased operational costs.

Additionally, the precision of manual sorting is inherently variable. When operators assess the length of wing feathers to determine gender, human error can lead to significant inaccuracies. Such inconsistencies not only affect the uniformity of weights in poultry but can also lead to dissatisfaction among customers and retailers expecting high standards for product quality.

Moreover, the pressure to meet market demands for consistent and homogenous body weight makes manual sorting a risky endeavor. As consumers become more discerning, the expectations for poultry products rise, necessitating a shift from outdated methods to more advanced solutions.

In response to these challenges, the Genesys system offers a game-changing approach to poultry sorting, integrating automation and cutting-edge technology to streamline operations and enhance accuracy.

The Power of Automation with Genesys

The Genesys technology brings the power of automation to poultry sorting, drastically transforming how hatcheries operate. By utilizing sophisticated algorithms, the platform ensures a consistent and accurate identification of chicks, achieving a remarkable precision rate of over 97%. This high level of accuracy directly addresses the issues faced by manual sorting, minimizing the risk of misclassifications.

Automation significantly increases throughput, allowing hatcheries to scale up their operations without the need for a large workforce. With the capacity to sort at much higher speeds, hatcheries can quickly meet the demands of the market without compromising on quality. This efficiency not only reduces labor costs but also enhances the overall productivity of the team.

Furthermore, the Genesys system’s design is modular and compact, fitting seamlessly into existing hatchery layouts. This flexibility in installation means that facilities can adopt new technologies without extensive renovations or downtime. As the poultry industry adapts to ongoing changes, having a system that can evolve with it is essential for long-term success.

Incorporating cloud capabilities allows for real-time data monitoring and analysis. This oversight enables teams to swiftly respond to performance discrepancies and optimize operations based on accurate insights. Hence, the Genesys system is not just an apparatus; it is a comprehensive solution that empowers agents to oversee operations with confidence.

Enhancing Customer Experience through Data Insights

Understanding the importance of data in modern operations, the Genesys technology equips hatcheries with critical insights into their processes. The system captures essential information about each sorting cycle, allowing for continuous improvement and refinement of operational strategies. Support teams can leverage this data to enhance customer interactions and build stronger relationships.

By analyzing performance indicators and production outcomes, hatcheries can make informed decisions that directly benefit their customers. For instance, if data reveals inconsistencies in weight distributions, teams can adjust sorting protocols to ensure higher levels of product uniformity. This proactive approach not only boosts customer satisfaction but also strengthens brand loyalty.

Additionally, the ability to monitor operations remotely further enhances the customer experience. Hatcheries can maintain quality control while responding quickly to any issues that arise, ensuring that they meet their commitments to retailers and consumers alike. The transparency provided by the Genesys technology reassures customers that their needs are prioritized and their expectations will be met consistently.

As the competition in the poultry industry intensifies, embracing data-driven strategies becomes imperative. The Genesys system serves as an invaluable resource for hatcheries looking to enhance their customer experience while streamlining their operational processes.

The Future of Poultry Sorting with Genesys

As we look towards the future, the poultry industry is poised for further transformation. The reliance on manual sorting methods will continue to diminish as more hatcheries adopt the Genesys system and similar technologies. This shift not only addresses current challenges but also positions the industry to embrace new innovations.

With the rise of automation, the potential for improved throughput and accuracy will attract new players to the market who may have previously struggled with manual processes. Furthermore, as environmental and ethical considerations gain prominence, technologies that optimize operations while aligning with sustainability goals will be in high demand.

The Genesys system exemplifies this proactive approach. By integrating automation with data analytics, hatcheries can operate more efficiently, reducing waste and improving overall sustainability. As industry demands evolve, so too will the capabilities of system like Genesys, ensuring they remain at the forefront of innovation.

Moreover, as consumers become more informed and conscientious, hatcheries will need to adapt to changing preferences. The Genesys technology will play a crucial role in helping them meet these expectations, offering not just high-quality products, but also transparency and accountability in their operations.

In conclusion, the future of poultry sorting is bright, driven by technological advancements and a commitment to excellence. The Genesys technology is not merely a response to current demands; it is a catalyst for change, ready to lead the industry into a new era of efficiency and customer satisfaction.

In summary, the poultry industry stands at a crossroads where innovation and efficiency must meet to address increasing demands. The Genesys system emerges as a revolutionary solution that not only enhances sorting accuracy and throughput but also enriches the customer experience through data-driven insights. By embracing automation, the industry can overcome traditional challenges and prepare for a sustainable future.

As hatcheries continue to evolve, technology like Genesys will be instrumental in shaping the landscape of poultry production, ensuring that they not only meet but exceed the expectations of consumers and businesses alike.

Post Comment